Introduction: When Saving Today Costs More Tomorrow

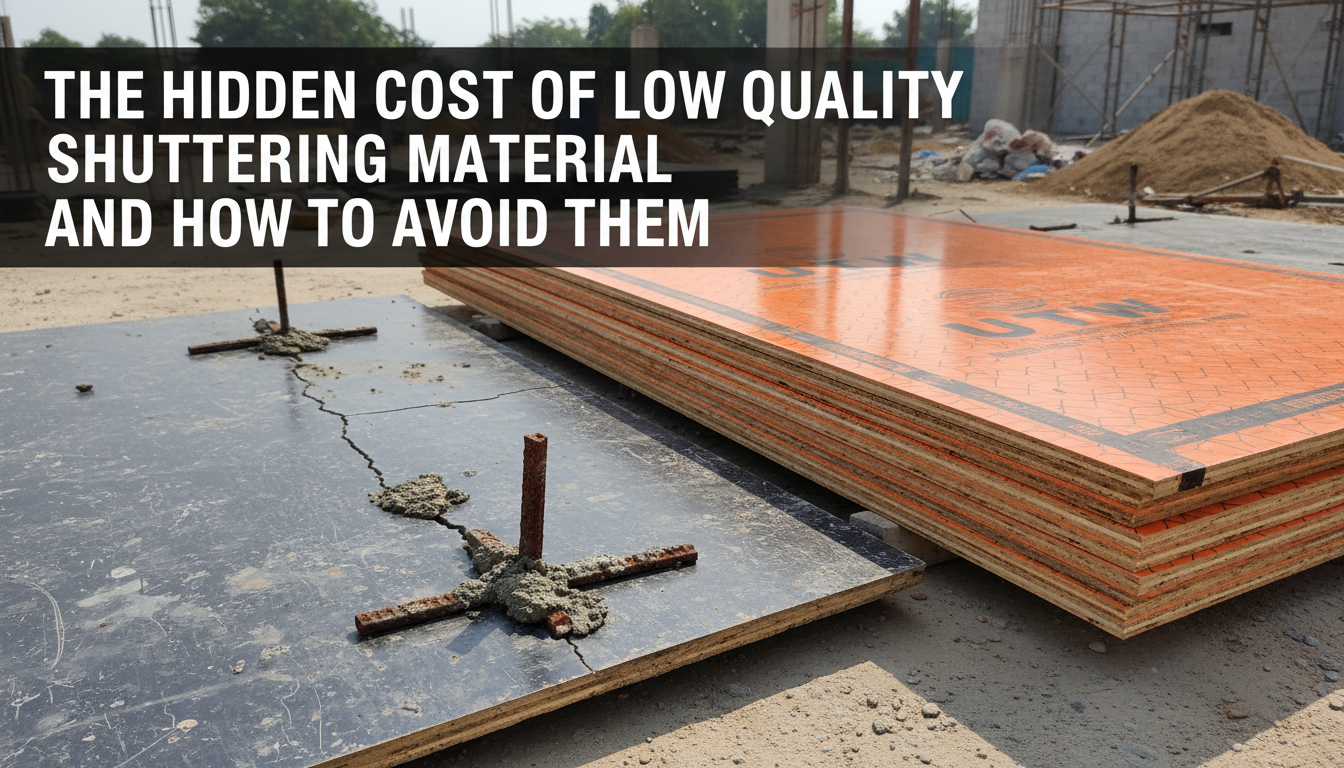

Over the years, I’ve seen countless construction projects that start with great ambition but struggle midway due to one common mistake involving compromising on shuttering materials. At first glance, cheaper materials seem like a practical cost-saving choice, especially for large-scale or time-sensitive projects. But as time passes, these “savings” turn into unexpected expenses from structural damage and repair work to delays that affect the entire project timeline.

In construction, every layer counts. And when the base formwork fails, everything built on it suffers. That’s why I’ve learned that choosing high-quality, high-density shuttering plywood isn’t a luxury anymore. Instead, it has become a long-term investment for quality and stability.

Save Yourself From These Hidden Costs That No One is Talking About

1. The True Price of Cheap Shuttering Material

It’s easy to get drawn to low-cost shuttering boards that promise to “do the job.” But what’s often ignored is their limited lifespan and poor load-bearing capacity. These materials might work fine for the first pour, but by the second or third use, they begin to warp, absorb moisture, and lose shape.

The outcome?

- Uneven concrete surfaces that require costly finishing work.

- Structural inconsistencies that affect alignment and stability.

- Frequent replacements add hidden expenses that far exceed the cost of premium materials.

In the long run, cheap shuttering materials don’t just affect the structure but end up compromising the builder’s reputation. A project that was meant to showcase efficiency ends up reflecting poor workmanship.

2. How Low-Quality Materials Delay Projects

Time is the most valuable currency in construction. Every hour of delay translates into financial strain on labour, machinery, and logistics. Unfortunately, low-quality shuttering plywood is often the root cause of these delays.

Once these boards start swelling or losing grip due to moisture exposure, workers have to spend additional hours fixing panels or re-pouring sections of concrete. In some cases, entire sections need to be redone, resulting in a domino effect of wasted time and additional expenses.

This is why many experienced builders I’ve worked with prefer to invest upfront in high-density shuttering plywood. It not only reduces maintenance but also ensures faster turnaround and smoother project flow.

3. The Structural Risks You Can’t See Immediately

The most dangerous thing about low-grade shuttering material is that its effects aren’t always visible right away. The first few pours might look acceptable, but the internal integrity of the structure begins to weaken over time. Moreover, water absorption leads to micro-cracks in concrete, poor bonding, and eventually reduced strength in the finished structure. In larger projects, such hidden flaws can turn into major safety risks, resulting in expensive repairs or even structural failures.

When I recommend high-density shuttering plywood, it is to ensure long-term strength and structural assurance.

4. Choosing Quality That Lasts: How to Avoid These Mistakes

I must tell you that avoiding these costly mistakes begins with awareness. Here are a few key points I always consider while selecting shuttering plywood:

- Check for certification – Always buy from trusted manufacturers who follow ISI or equivalent quality standards.

- Inspect density and finish – High-density plywood resists warping and retains shape across multiple uses.

- Ask about waterproofing – Ensure that the material is treated with durable waterproof coatings.

- Understand bonding quality – Phenol-formaldehyde bonded plywood offers stronger resistance to weather and pressure.

Thus, making these small checks upfront can prevent significant issues later. Remember, quality control at the beginning saves countless hours and lakhs in rework.

How United Timber Works Ensures Long-Term Value?

At United Timber Works, we’ve built our reputation on one belief, i.e.: quality plywood builds quality projects. That’s why our high-density shuttering plywood is engineered to deliver:

- Exceptional durability and multiple reuses

- Superior waterproof protection and dimensional stability

- Smooth, consistent finishes for flawless concrete casting

Every panel undergoes rigorous testing to ensure it meets global construction standards. We use advanced bonding resins and precision calibration to create plywood that performs under pressure. Whether you’re building residential towers, commercial complexes, or infrastructure projects, United Timber Works ensures reliability that pays off in the long run.

Key Takeaways: Build Once, Build Right

Today, in construction, cutting corners might seem tempting, but true efficiency lies in building it right the first time. Know that low-quality shuttering materials may offer short-term savings, but they often lead to long-term headaches.

As someone who has seen both sides of the equation, I can say with certainty: investing in high-density shuttering plywood is insurance for your project’s success. Moreover, with brands like United Timber Works, you’re not just buying plywood; you’re securing the strength, precision, and integrity your project deserves.